Model: COMPACT

Specifications:

After the vehicle wash service, the water will have a high concentration of suspended solids, oils, greases, detergents and surfactants. This water from washing is cloudy, foamy and has a characteristic odor.

The effluent will receive a preliminary treatment in order to remove the coarsest materials, such as oils, grease and sedimentable solids (sand), through the separator box (SAO) and, desander box, to remove excess oil and coarse solids, respectively.

After going through the preliminary treatment, the effluent is directed to the raw water tank where it will be pumped by the system’s centrifugal or submerged pump: the STC 1000 STANDARD treatment unit. The STC 1000 STANDARD treatment system will be responsible for removing suspended solids and surfactants, producing water with low turbidity, without odor and with reduced surfactant content.

This system was developed based on a specific and compact system for treating and reusing water, taking into account the origin of waste from washing small heavy vehicles. It aims to remove sedimentable solids, suspended solids and a portion of surfactants. It also sterilizes the water, ensuring the sanitary safety of the treated water. The CEF ETCE equipment is a standard physical-chemical treatment unit and follows the following steps:

- Coagulation;

- Flocculation;

- Sedimentation;

- Filtration; and

- Disinfection.

The Compact System for Effluent Treatment does not require a high investment, takes up little space, is easy to operate, economical, a sustainable alternative and reuses up to 90% depending on the water to be reused.

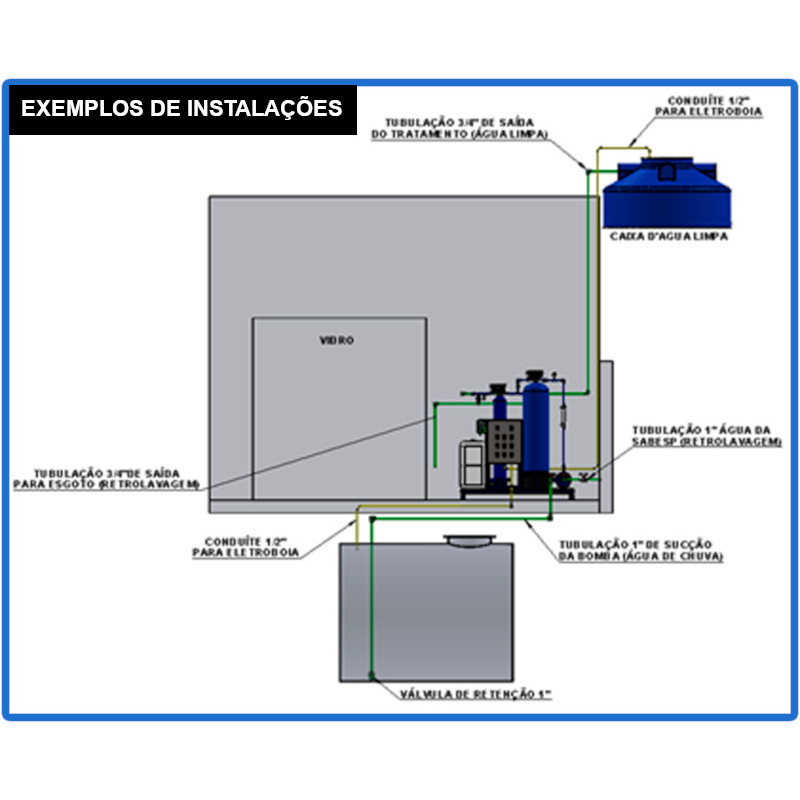

INSTALLATION REQUIREMENTS:

- Power supply – three-phase or single-phase;

- Water and oil separator box;

- Cistern for raw and treated water externally or internally with volumes of 5m³);

- Receiving piping and discharge from the treatment plant.